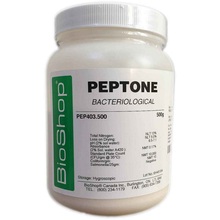

Yeast Promoter enzyme for ethanol industry

| Unit Price: | 8.9 USD |

|---|---|

| Min. Order: | 100 Kilogram |

| Packaging: | 1KG;25KG |

|---|---|

| Productivity: | 10000T/MONTH |

| Brand: | SUNSON |

| Transportation: | Ocean,Land,Air,Express,Express |

| Place of Origin: | China |

| Supply Ability: | 10000T/MONTH |

| Certificate: | ISO22000;MUI,FAMI-QS;NON-GMO;FSSC22000;KOSHER;HALAL |

| HS Code: | 3507909090 |

| Port: | Tianjin,Shanghai,Guangzhou |

Click on the follow link to find out more information: https://www.sunsonchinaenzymes.com/ethanol-alcohol-enzymes/

Company Info

- Company Name: Sunson Industry Group Co., Ltd

- Representative: Zhongping Du

- Product/Service: Food Enzymes , Animal Feed Enzymes , Baking Enzymes , Textile Enzymes , Leather Enzymes , Detergent Enzymes

- Capital (Million US $): 21,000,000RMB

- Year Established: 1996

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 31% - 40%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 5

- No. of R&D Staff: 31 -40 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: Cangzhou city, Hebei province, China

- Contact Person: Mr. Zhou

- Tel: +86-10-58246890

Premium Related Products

Other Products

Hot Products

2016 Hot Sell Canned MackerelTube Tomato Paste with High Quality340 G Plastic Bottle Tomato Ketchup of Vego Brand2015 New Crop Tomato Paste in Drum2.2kg*6 28%-30% Canned Tomato Paste4500g 28%-30% Canned Tomato Paste3000g 28%-30% Canned Tomato Paste400g 28-30% Canned Tomato Paste198g 28%-30% Canned Tomato Paste245ml Tomato Juice800g 28%-30% Canned Tomato Paste(36-38%CB) Tomato Paste in Drum70g*100 28%-30% Tomato Paste10g Chicken Flavor Bouillon Cube, Seasoning Cube of Good Flavor70g, 210g, 400 G Double Concentrated Canned Tomato Paste of Vego BrandFine Tom 70g Sachet Packaging Tomato Paste Manufacturer From China